Engineering the workplace to achieve safety & for optimal working conditions can impact business operations by influencing productivity, output, product quality, process equipment design and the state of the physical environment. We provide services to assess & reduce risks of exposures to hazardous conditions & hazardous environments at work, including environmental testing for excess accumulation of contaminants. Objective workplace inspections are conducted to determine whether conditions are acceptable and compliant. For safety engineering we provide site inspections, job hazard analysis (JHA), equipment “pre-start” engineering reviews (PSRs), confined space assessments, etc. Brief descriptions of some of these services are provided below. If you are unsure please contact us:

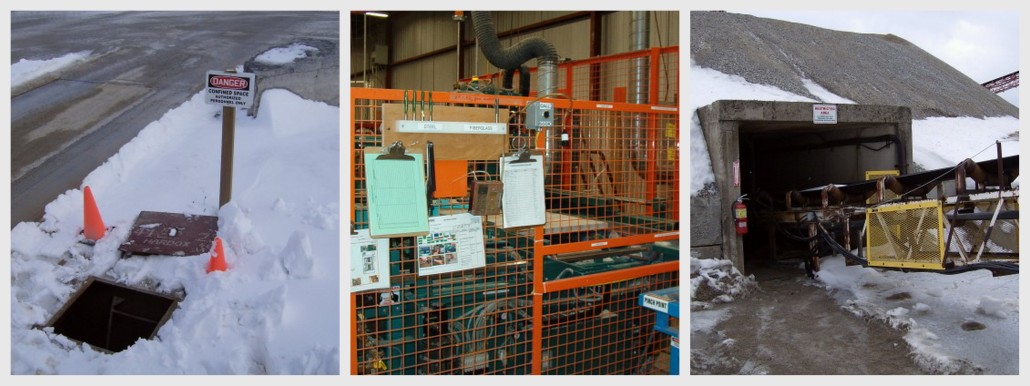

Confined Space Entry

- Classification and identification of confined spaces, including assessment of hazards, development of entry permit procedure, atmospheric monitoring, examination of entry/egress requirements

Job Hazard Analysis

- Systematic review of jobs for identification of the critical tasks, hazards associated with each critical task, level of risk related to each hazard, determination of existing control measures, numerical quantification of residual risk levels, requirements & recommendations for improvements and risk reduction

Personal Protective Equipment

- PPE recommendations are determined by type of hazard, routes of entry & level of exposure. Selection of respirator & hearing protectors also considers exposure levels. Glove/clothing consider permeability to chemical agents.

Safety Inspections

- Workplace inspection entail review of administrative requirements under Health & Safety enforcement Act, physical inspection of workplace, identification of contraventions, potential ramifications including orders & enforcement actions (time limits, compliance plans, stop work)

Pre-Start Health & Safety Reviews

- Examination and study of new installation, equipment, process, structure by an engineer &/or hygienist to identify hazards and mitigate risks before start-up, after modification and to delineate protective features